Cutting metal is a job that requires precision, power, and the right tool. Whether you’re working in a professional metal fabrication shop or tackling a DIY project at home, having the best grinder for metal cutting can make a huge difference in efficiency, safety, and end results.

There are several types of grinders available on the market, and choosing the right one can feel overwhelming. This detailed guide will help you understand the types, uses, features to consider, safety practices, and where to find the most trusted Angle grinder and Bench grinder suppliers in India.

Why Use a Grinder for Cutting Metal?

Grinders are powerful tools that can cut, grind, polish, and shape metal surfaces. Unlike hand tools, grinders offer speed and accuracy, making them essential for metalworking jobs. From slicing through steel pipes to trimming sheet metal or finishing welded joints, a grinder ensures clean, efficient cuts.

Types of Grinders Used for Metal Cutting

Understanding different types of grinders will help you choose the one best suited to your project.

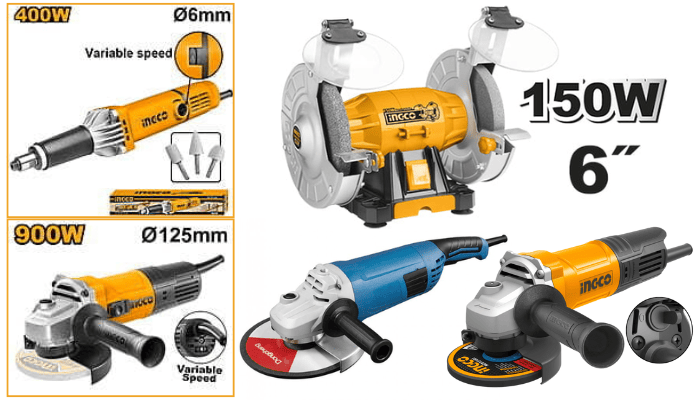

1. Angle Grinder

The angle grinder is the most commonly used grinder for metal cutting. It’s a handheld power tool that operates with various disc sizes and is capable of cutting, grinding, sanding, and polishing.

Benefits:

- Ideal for straight and curved cuts in metal

- Versatile with multiple disc attachments

- Easily available from top Angle grinder dealers in India

Applications:

Cutting metal rods, trimming sheet metal, removing rust, and polishing welded joints.

2. Bench Grinder

A bench grinder is a stationary tool typically mounted on a workbench. While it is not commonly used for cutting metal sheets or pipes, it is excellent for surface preparation, sharpening, and shaping.

Benefits:

- Dual grinding wheels for coarse and fine tasks

- Stable and powerful for prolonged use

- Popular among industrial users via reliable Bench grinder suppliers in India

Applications:

Sharpening tools, deburring metal edges, shaping materials, and smoothing welds.

3. Die Grinder

A die grinder is a compact rotary tool designed for precision tasks. It is often used in fabrication and metal design work, especially for small or hard-to-reach areas.

Benefits:

- Lightweight and easy to handle

- High-speed operation for precision

- Great options available at a competitive price in India

Applications:

Engraving, deburring, polishing, cutting small pieces, and detail work on metal surfaces.

Key Features to Consider When Choosing a Grinder

Whether you need a grinder for heavy-duty cutting or light finishing tasks, consider the following factors:

1. Power and Performance

Higher wattage or amperage indicates more power. For heavy-duty metal cutting, choose a grinder with higher power output. If you’re only doing light polishing or trimming, a lower-powered tool will suffice.

2. Disc Size

The disc size determines how deep the grinder can cut. Common sizes range from 4 inches to 9 inches. Larger discs are suitable for heavy cuts, while smaller ones offer better control for precision work.

3. Speed Control

Variable speed grinders allow you to control RPMs, which is useful when switching between cutting, polishing, or grinding.

4. Safety Features

Always choose grinders with safety guards, lock-on switches, and anti-kickback technology. These features reduce the risk of accidents during operation.

5. Handle Design

Ergonomic handles with anti-vibration features help reduce fatigue during extended use. A good grip also increases control and safety.

How to Use a Grinder for Metal Cutting

Using a grinder effectively requires both knowledge and safety precautions. Here are some essential steps:

- Choose the Right Disc: Use a metal cutting disc or wheel that matches the grinder type and project requirement.

- Secure the Material: Clamp the metal firmly to prevent movement.

- Mark Your Cut Line: Use a chalk or marker to outline the area to be cut.

- Wear Safety Gear: Always wear gloves, goggles, ear protection, and a face shield.

- Start Slow: Let the grinder reach full speed before you begin the cut.

- Control Your Movement: Maintain a steady pace and avoid forcing the tool.

- Cool the Metal: Metal heats up during cutting, so take breaks if needed.

Common Grinder Uses in Metalworking

- Cutting rebar, steel pipes, and metal sheets

- Grinding welds and smoothing rough edges

- Removing rust and paint

- Sharpening tools and blades

- Creating decorative metal designs

Grinder Maintenance Tips

Keeping your grinder in good condition ensures performance and safety:

- Regularly check and replace worn-out discs

- Clean the air vents to prevent overheating

- Store the tool in a dry place

- Lubricate moving parts (as per manufacturer instructions)

- Inspect the power cord and handle for any damage

Where to Find the Best Grinder Deals in India

With so many options available in the Indian market, buying from a trustworthy supplier ensures product quality and after-sales support. Whether you’re looking for a robust angle grinder, a high-performance bench grinder, or a precision die grinder, you should explore verified:

- Angle grinder dealers in India

- Bench grinder suppliers in India

- Sellers offering the best Die grinder price in India

These dealers usually offer a wide range of grinders for both personal and industrial use, along with accessories like cutting discs, safety guards, and more.

ToolsMatic – Your Trusted Supplier for Grinders in India

If you’re wondering where to buy from, ToolsMatic is one of the most reliable and experienced suppliers of metalworking tools in India.

Why Choose ToolsMatic?

- Wide selection of grinders for every type of job

- Competitive pricing across all categories

- Excellent after-sales support and product warranties

- Bulk order discounts for workshops and industries

- Fast delivery across India

Whether you're searching for top-quality products from trusted Angle grinder dealers in India, dependable Bench grinder suppliers in India, or a reasonable grinder price in India, ToolsMatic can meet your needs with confidence and reliability.

Conclusion

Choosing the best grinder for metal cutting isn’t just about power — it’s about precision, safety, comfort, and durability. Understanding the differences between angle grinders, bench grinders, and die grinders allows you to select the right tool for your job.

If you want top-performing tools backed by a reliable supplier, ToolsMatic is your go-to destination. With a wide inventory, transparent pricing, and outstanding customer service, they help professionals and hobbyists across India get the job done right.